After welding, the parts are vibratory ground or tumble ground to ensure a smooth surface finish. This extra step is critical for parts that will be used in high-end applications where appearance and durability are critical. Overall, the end product was exactly what the customer envisioned: a high-quality sheet metal welded component with a curved arc that is both aesthetically pleasing and functional. The attention to detail and craftsmanship of each part sets HY Metals apart from other manufacturing companies. So if you are looking for a trusted partner for all your sheet metal fabrication needs, look no further than HY Metals. Contact us today to learn more about our services and how we can help you achieve your goals.

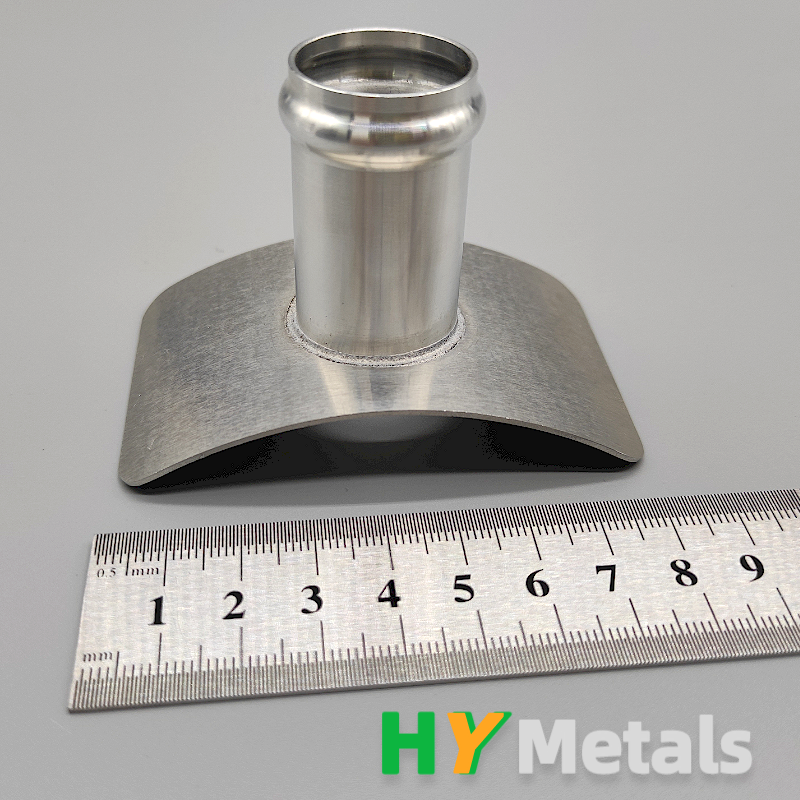

After welding, the parts are vibratory ground or tumble ground to ensure a smooth surface finish. This extra step is critical for parts that will be used in high-end applications where appearance and durability are critical. Overall, the end product was exactly what the customer envisioned: a high-quality sheet metal welded component with a curved arc that is both aesthetically pleasing and functional. The attention to detail and craftsmanship of each part sets HY Metals apart from other manufacturing companies. So if you are looking for a trusted partner for all your sheet metal fabrication needs, look no further than HY Metals. Contact us today to learn more about our services and how we can help you achieve your goals. | Part Name | High-quality sheet metal welded component Custom aluminum welding assembly |

| Standard or Customized | Customized |

| Size | 80*40*80mm,according to design drawings |

| Tolerance | +/- 0.1mm |

| Material | Aluminum tubes and aluminum sheet metal |

| Surface Finishes | Clear chromate, chemical film |

| Application | Sheet metal prototype, brackets |

| Process | Laser cutting-bending-Forming tubs- welding-chromate |